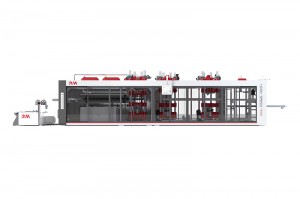

RM-T7050 3 chaw nres tsheb tsis siv neeg thermoforming tshuab

Tshuab Parameters

| ◆ Qauv: | Qauv: RM-T7050 |

| ◆Max.Forming Area: | 720mm × 520mm |

| ◆ Max.Forming Qhov siab: | 120 hli |

| ◆Max. Sheet Thickness (mm): | 1.5 hli |

| ◆ Daim ntawv dav: | 350-760 hli |

| ◆ Qhov siab tshaj ntawm daim ntawv yob txoj kab uas hla: | 800 hli |

| ◆ Kev siv fais fab: | 60-70 KW / H |

| ◆ Pwm txav deb: | Stroke ≤150 hli |

| ◆ Claping Force: | 60t ua |

| ◆ Khoom ua kom txias txoj kev: | Dej |

| ◆ Ua tau zoo: | Max 25cycles/min |

| ◆ Hluav taws xob rauv cua sov lub zog siab tshaj plaws: | 121.6 KW TSI |

| ◆ Lub zog siab tshaj plaws ntawm tag nrho lub tshuab: | 150 KW TSI |

| ◆ PLC: | TSEEM CEEB |

| ◆ Servo Tsav: | Yaskawa |

| ◆Reducer: | GNORD |

| ◆ Daim ntawv thov: | cov tais, ntim, thawv, hau, thiab lwm yam. |

| ◆ Core Cheebtsam: | PLC, Cav, Bearing, Gearbox, Tsav, Iav, Twj |

| ◆ Khoom siv tsim nyog: | PP.PS.PET.CPET.OPS.PLA |

| Max.Pwm Qhov ntev | Ceev (Shot / Min) | Max.Daim ntawv Thickness | Max.Foming Qhov siab | Tag nrho qhov hnyav | Khoom siv tsim nyog |

| 720 x 520 mm | 20-35 : kuv | 2 hli | 120 hli | 11 T | PP, PS, PET, CPET, OPS, PLA |

Product Video

Lub ntsiab nta

✦ Diversified ntau lawm: Nrog ntau lub chaw ua haujlwm, 3-chaw nres tsheb thermoforming tshuab tuaj yeem ua cov khoom sib txawv lossis siv cov pwm sib txawv tib lub sijhawm, ua rau cov txheej txheem ntau lawm thiab muaj ntau yam.

✦ Kev hloov pwm ceev: Lub tshuab 3-chaw nres tsheb thermoforming yog nruab nrog lub tshuab hloov pwm ceev, uas tuaj yeem hloov pwm sai sai kom tau raws li qhov xav tau ntawm cov khoom sib txawv.Qhov no txo qis downtime thiab nce productivity.

✦ Kev tswj tsis siv neeg: Cov cuab yeej siv qhov kev tswj hwm tsis siv neeg siab heev, uas tuaj yeem tswj hwm qhov tsis xws li cua sov, lub sijhawm molding thiab siab.Automated tswj tsis tsuas yog txhim kho kev ruaj ntseg thiab sib xws ntawm molding, tab sis kuj txo tus neeg teb xov tooj cov kev cai thiab txo cov neeg ua yuam kev.

✦ Kev txuag hluav taws xob thiab txuag hluav taws xob: Lub 3-chaw nres tsheb thermoforming tshuab txais cov cuab yeej txuag hluav taws xob, uas txo qis kev siv hluav taws xob thiab cov nqi tsim khoom los ntawm kev ua kom zoo cua sov, txias thiab siv zog.Qhov no yog ob qho txiaj ntsig ntawm kev lag luam thiab kev tiv thaiv ib puag ncig rau kev lag luam.

✦ Yooj yim rau kev khiav lag luam: 3-chaw nres tsheb thermoforming tshuab yog nruab nrog kev ua haujlwm tsis zoo, thiab kev ua haujlwm yooj yim kawm.Qhov no tuaj yeem txo cov nqi kev cob qhia cov neeg ua haujlwm thiab txhim kho kev tsim khoom.

Kev thov cheeb tsam

RM-T7050 3-chaw nres tsheb thermoforming tshuab yog dav siv hauv kev lag luam ntim khoom noj, feem ntau yog siv rau kev tsim cov ntim yas pov tseg, xws li cov mis tshuaj yej hau, square thawv, square box hau, lub hli ncuav mog qab zib thawv, tais thiab lwm yam khoom yas.

Kev qhia

Pib koj lub 3 chaw nres tsheb thermoforming tshuab los ntawm kev ua kom muaj kev ruaj ntseg kev sib txuas thiab lub hwj chim.

Ua ntej kev tsim khoom, ua ib qho kev ntsuam xyuas ntawm cov cua sov, cua txias, lub zog siab, thiab lwm yam haujlwm kom ntseeg tau tias lawv nyob rau hauv qhov zoo tshaj plaws.

Nrog precision, nruab qhov xav tau pwm ruaj ntseg.Cov kauj ruam no yog qhov tseem ceeb los tiv thaiv kev cuam tshuam thaum lub sijhawm tsim khoom thiab ua kom cov khoom tsim tau zoo ib yam.

Rau cov txiaj ntsig tshwj xeeb, npaj ib daim ntawv yas zoo tagnrho rau molding.Qhov kev xaiv zoo ntawm cov khoom siv txhim kho qhov kawg ntawm cov khoom zoo thiab kev zoo nkauj, teeb tsa koj cov khoom sib nrug ntawm kev sib tw.

Ua kom pom tseeb qhov tseeb ntawm kev txiav txim siab qhov loj thiab tuab ntawm cov ntawv yas, kom ntseeg tau tias lawv zoo kawg nkaus ua raws li cov pwm xav tau.

Xauv tag nrho lub peev xwm ntawm koj cov txheej txheem thermoforming los ntawm kev teeb tsa qhov kub thiab txias thiab lub sijhawm tus kws tshaj lij.Xav txog cov khoom siv yas tshwj xeeb thiab cov pwm yuav tsum tau ua, ua qhov kev hloov kho kom tsim nyog rau cov txiaj ntsig zoo.

Ua tib zoo tso cov ntawv yas preheated rau ntawm pwm nto, xyuas kom nws nyob tiaj tus kom tau txais txiaj ntsig zoo.

Raws li cov txheej txheem molding pib, saib yuav ua li cas cov pwm siv lub siab thiab kub hauv lub sijhawm teem, hloov cov ntawv yas rau hauv cov duab uas xav tau.

Tom qab tsim, saib cov yas tsim solidify thiab txias los ntawm pwm.Thiab tom qab ntawd stacking thiab palletizing.

Peb yuav tsum dhau los ntawm kev tshuaj xyuas nruj rau txhua qhov khoom tiav.Tsuas yog cov uas ua tau raws li cov qauv zoo tshaj plaws thiab cov qauv zoo tawm ntawm peb cov kab ntau lawm.

Tom qab txhua qhov kev siv, yuav tsum tau ua qhov tseem ceeb ntawm cov cuab yeej kev nyab xeeb thiab kev txuag hluav taws xob los ntawm kev kaw lub tshuab thermoforming thiab txiav tawm ntawm lub zog hluav taws xob.

Tib lub sijhawm nrog kev tu cov pwm thiab cov cuab yeej siv tau zoo, tsis muaj chaw seem rau cov yas lossis cov khib nyiab uas tuaj yeem cuam tshuam cov khoom zoo.

Tsis tu ncua ntsuas ntau yam khoom siv los lav lawv cov kev ua haujlwm zoo.Peb cov kev siv zog tas mus li hauv kev saib xyuas kom ua tau zoo thiab tsis muaj kev cuam tshuam.