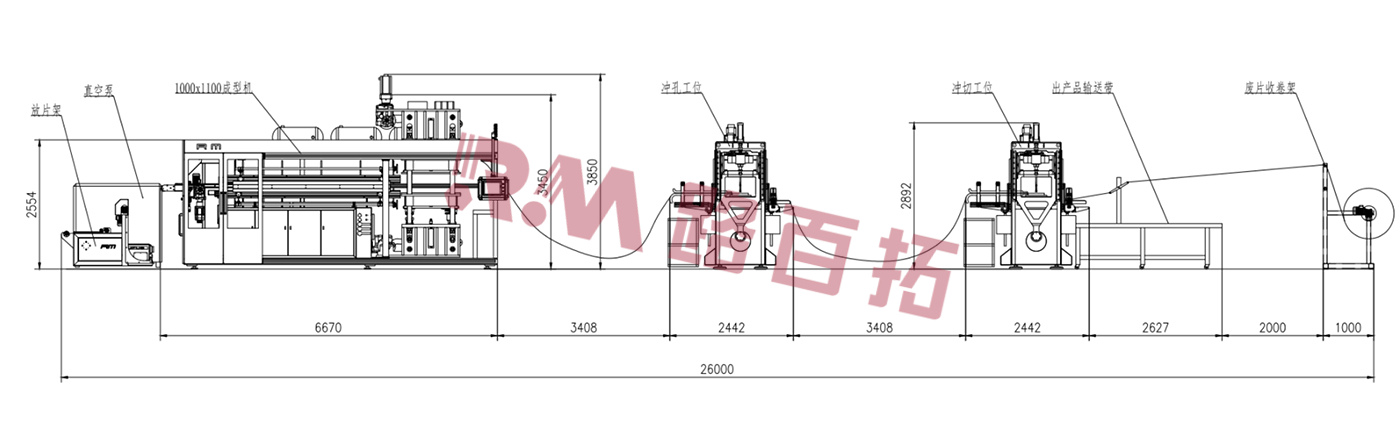

RM-T1011 + GC-7 + GK-7 Thermoforming Tshuab

Tshuab Parameters

| ◆ Qauv: | Qauv: RM-T1011 |

| ◆ Max. pwm loj: | 1100mm × 1170 hli |

| ◆ Max. tsim cheeb tsam: | 1000mm × 1100mm |

| ◆Min. Tsim cheeb tsam: | 560mm × 600mm |

| ◆ Max. tus nqi ntau lawm ceev: | ≤ 25 zaug / min |

| ◆ Max.Forming Qhov siab: | 150 hli |

| ◆ Daim ntawv dav (mm): | 560mm-1200mm |

| ◆ Pwm txav deb: | Stroke ≤220mm |

| ◆ Max. clamping quab yuam: | sib sau-50T, xuas nrig ntaus-7T thiab txiav-7T |

| ◆ Fais fab mov: | 300KW (lub zog cua sov) + 100KW (lub zog ua haujlwm) = 400kw |

| ◆ suav nrog lub tshuab xuas nrig ntaus 20kw, txiav tshuab 30kw | |

| ◆ Fais fab mov specifications: | AC380v 50Hz, 4P (100mm2+ 1PE (35mm2) |

| ◆ Peb-xaim tsib-xaim system | |

| ◆ PLC: | TSEEM CEEB |

| ◆ Servo Tsav: | Yaskawa |

| ◆Reducer: | GNORD |

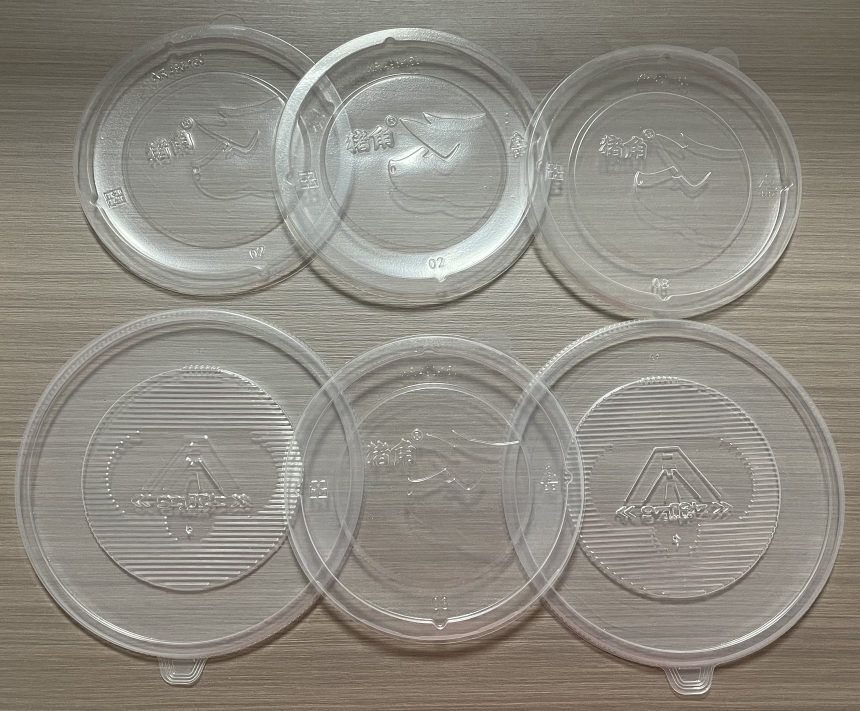

| ◆ Daim ntawv thov: | cov tais, ntim, thawv, hau, thiab lwm yam. |

| ◆ Core Cheebtsam: | PLC, Cav, Bearing, Gearbox, Tsav, Iav, Twj |

| ◆ Khoom siv tsim nyog: | PP.PS.PET.CPET.OPS.PLA |

| Max. Mould Dimensions | Clamping Force | Punching Peev Xwm | Txiav Capacity | Max. Tsim Qhov Siab | Max. Cua Siab | Qhuav Cycle Speed | Max. Punching / Txiav Dimensions | Max. Punching / Txiav ceev | Khoom siv tsim nyog |

| 1000 * 1100 hli | 50 t ib | 7T | 7T | 150 hli | 6 Bar | 35r / min | 1000 * 320 hli | 100 spm | PP, HI PS, PET, PS, PLA |

Product Video

Daim duab ua haujlwm

Lub ntsiab nta

✦ Kev ua tau zoo: Lub tshuab loj thermoforming tau txais txoj kev ua haujlwm ntawm cov kab ntau lawm, uas tuaj yeem ua tiav thiab ua tiav cov txheej txheem molding ntawm cov khoom. Los ntawm kev tswj tsis siv neeg thiab kev siv tshuab ua haujlwm siab, kev tsim khoom tuaj yeem txhim kho kom tau raws li qhov xav tau ntawm ntau lawm.

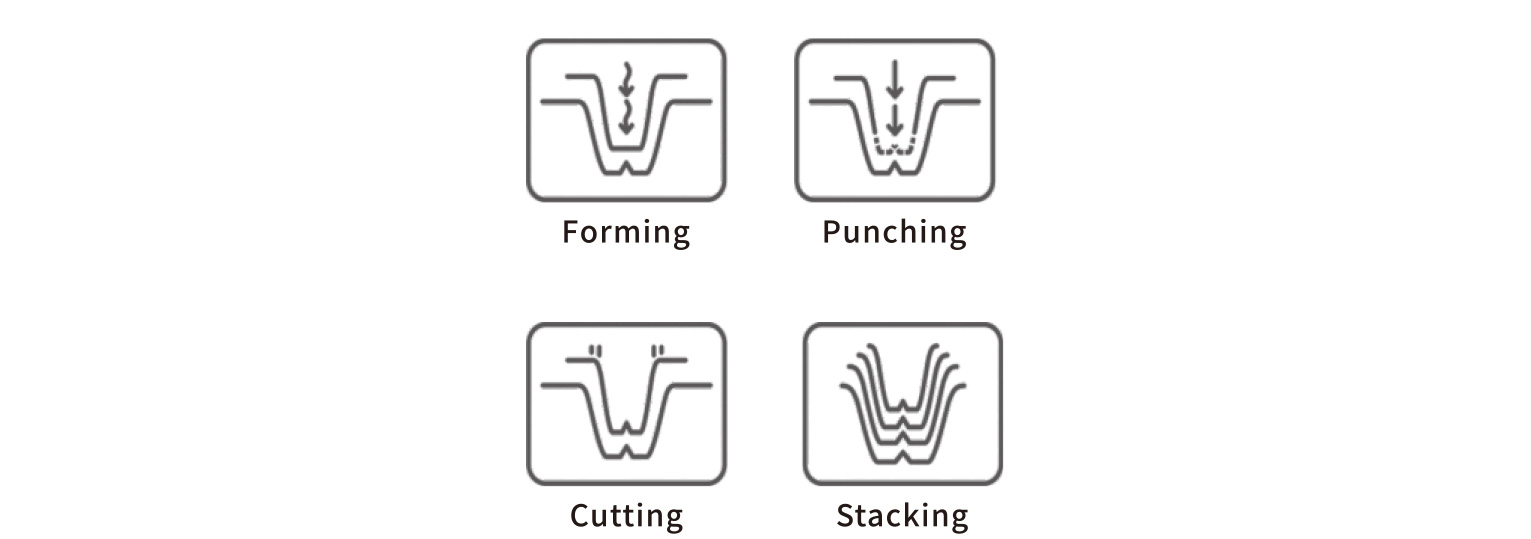

✦ Multifunctional ua haujlwm: lub tshuab muaj ntau yam haujlwm xws li kev tsim, xuas nrig ntaus, ntug xuas nrig ntaus thiab palletizing.

✦ Precise molding thiab cov khoom zoo: Lub tshuab thermoforming loj siv tshuab molding siab heev, uas tuaj yeem tswj cov cua sov, siab thiab cua sov lub sij hawm kom paub meej tias cov khoom yas yog tag nrho yaj thiab sib npaug ntawm cov pwm, yog li tsim cov khoom lag luam nrog cov khoom zoo thiab qhov tseeb.

✦ Kev ua haujlwm tsis siv neeg thiab kev tswj xyuas ntse: Lub tshuab tau nruab nrog lub tshuab ua haujlwm siab heev, uas tuaj yeem paub txog kev ua haujlwm xws li kev pub mis tsis siv neeg, tsis siv neeg sib sau, tsis siv neeg xuas nrig ntaus, tsis siv neeg ntug xuas nrig ntaus thiab tsis siv neeg palletizing. Kev ua haujlwm yog yooj yim thiab yooj yim, txo cov kev cuam tshuam ntawm phau ntawv, txhim kho kev tsim khoom thiab txo cov nqi tsim khoom.

✦ Kev nyab xeeb thiab kev tiv thaiv ib puag ncig: Lub tshuab thermoforming loj yog ua los ntawm cov ntaub ntawv zoo, uas muaj kev ruaj khov thiab ruaj khov. Nws tseem tau nruab nrog kev tiv thaiv kev nyab xeeb kom muaj kev nyab xeeb ntawm cov neeg ua haujlwm. Nyob rau tib lub sijhawm, lub tshuab muaj lub zog txuag tsim, uas tuaj yeem txo qis kev siv hluav taws xob thiab txo qhov cuam tshuam rau ib puag ncig.

Kev thov cheeb tsam

Lub tshuab thermoforming loj RM-T1011 thermoforming tshuab tau dav siv hauv kev lag luam catering, kev lag luam ntim khoom noj thiab khoom siv hauv tsev. Vim nws cov kev ua haujlwm siab, ntau lub luag haujlwm thiab cov yam ntxwv meej, nws tuaj yeem ua tau raws li cov kev xav tau ntawm kev lag luam sib txawv rau cov khoom yas thiab muab kev txhawb zog rau cov lag luam los txhim kho kev tsim khoom thiab cov khoom zoo.

Kev qhia

Kev npaj khoom siv:

Txhawm rau pib koj lub tshuab thermoforming, ua kom ntseeg tau ib qho kev txhim khu kev qha loj loj thermoforming tshuab RM-T1011 los ntawm kev lees paub nws qhov kev ruaj ntseg kev twb kev txuas thiab muab nws tso rau. Kev kuaj xyuas tag nrho ntawm cov cua sov, cua txias, thiab lub tshuab ua haujlwm siab yog qhov tseem ceeb los xyuas lawv cov haujlwm zoo li qub. Tiv thaiv koj cov txheej txheem ntau lawm los ntawm kev txhim kho cov pwm tsim nyog, kom ntseeg tau tias lawv ruaj khov rau kev ua haujlwm du.

Raw Khoom Npaj:

Ua kom tiav qhov zoo tshaj plaws hauv thermoforming pib nrog kev npaj cov khoom siv raw. Ua tib zoo xaiv ib daim ntawv yas zoo tshaj plaws rau molding, thiab xyuas kom meej nws qhov loj thiab tuab raws li cov pwm tshwj xeeb. Los ntawm kev xyuam xim rau cov ntsiab lus no, koj teeb tsa theem rau cov khoom kawg uas tsis muaj tseeb.

Thaum tshav kub kub chaw:

Xauv lub peev xwm tiag tiag ntawm koj cov txheej txheem thermoforming los ntawm cov kws tshaj lij kev teeb tsa cov cua sov thiab lub sijhawm los ntawm kev tswj vaj huam sib luag. Kho koj qhov chaw kom haum rau cov khoom siv yas thiab pwm, ua tiav cov txiaj ntsig zoo.

Txoj Kev - Qhov Punching - Ntug Punching - Stacking thiab Palletizing:

Maj mam muab cov ntawv yas preheated rau ntawm cov pwm saum npoo, kom ntseeg tau tias nws zoo sib xws thiab tsis muaj wrinkles los yog distortions uas yuav cuam tshuam cov txheej txheem tsim.

Pib ua cov txheej txheem molding, ua tib zoo siv lub siab thiab cua sov hauv lub sijhawm teem sijhawm los tsim cov ntawv yas kom meej rau hauv daim ntawv xav tau.

Thaum ua tiav, cov khoom yas tshiab tau muab tso rau hauv cov pwm thiab txias, ua ntej mus rau lub qhov xuas nrig ntaus, ntug xuas nrig ntaus, thiab sib dhos kom yooj yim palletizing.

Tshem tawm cov khoom tiav:

Tshawb xyuas txhua yam khoom tiav ua tiav kom paub tseeb tias nws ua raws li qhov xav tau thiab ua raws li cov qauv tsim tau zoo, ua kom muaj kev hloov kho raws li xav tau.

Kev tu thiab tu:

Tom qab ua tiav ntawm cov txheej txheem tsim khoom, lub tshuab hluav taws xob lub tshuab thermoforming thiab txiav tawm los ntawm lub zog hluav taws xob kom txuag hluav taws xob thiab tswj kev nyab xeeb.

Ua tib zoo ntxuav cov pwm thiab cov cuab yeej siv los tshem tawm cov khoom seem yas lossis cov khib nyiab, khaws cov pwm kom ntev thiab tiv thaiv qhov tsis xws luag hauv cov khoom yav tom ntej.

Ua raws li lub sijhawm ua haujlwm tsis tu ncua los tshuaj xyuas thiab pabcuam ntau yam khoom siv, lav tias lub tshuab thermoforming tseem nyob hauv qhov kev ua haujlwm zoo, txhawb kev ua haujlwm thiab kev ua haujlwm ntev rau kev tsim khoom tas mus li.