Zoo siab txais tos rau kev sib tham thiab sib tham

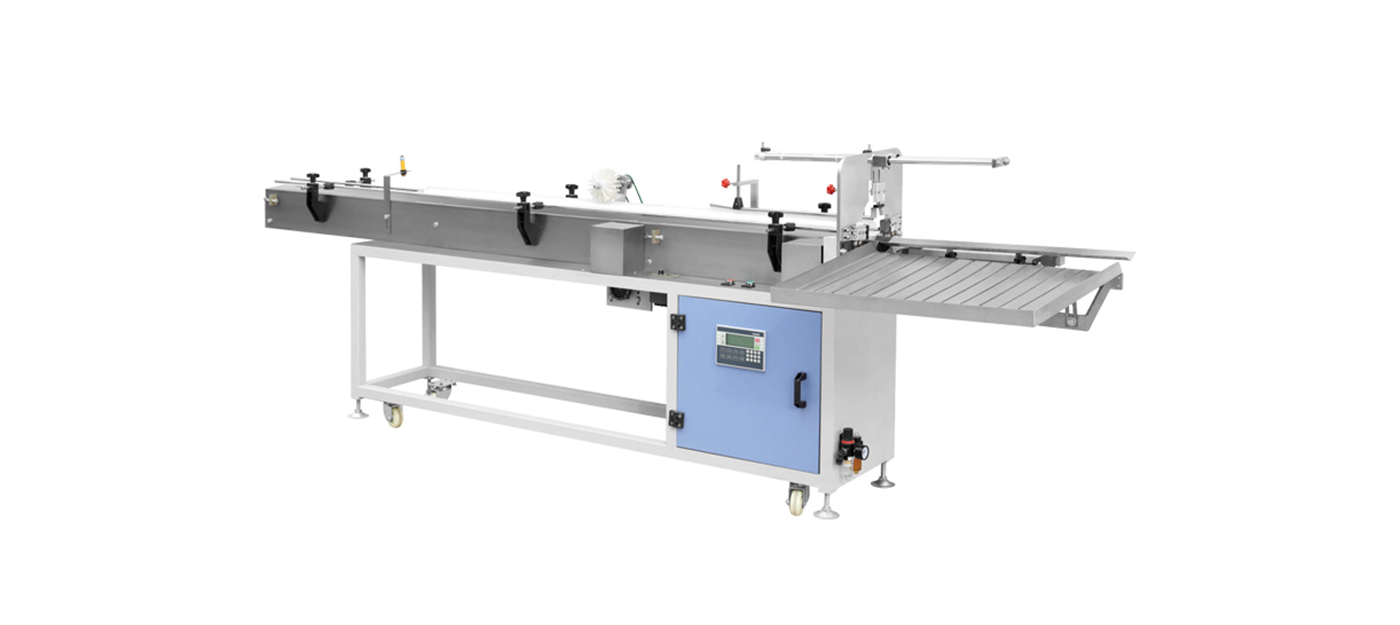

RM-4 Plaub-chaw nres tsheb Thermoforming tshuab

Kev piav qhia

Lub 4-chaw nres tsheb zoo thiab tsis zoo siab thermoforming tshuab yog cov cuab yeej siv tau zoo uas tuaj yeem siv los tsim cov thawv ntim cov txiv hmab txiv ntoo pov tseg, paj lauj kaub, khob kas fes hau thiab domed hau nrog qhov, thiab lwm yam. Cov cuab yeej yog nruab nrog lub pwm hloov ceev thiab muaj qhov zoo ntawm lub thawv cua sov tsim. Cov cuab yeej siv no siv cov thev naus laus zis zoo thiab tsis zoo thermoforming thev naus laus zis los ua cov ntawv yas rau hauv cov duab uas xav tau, qhov loj me thiab cov qauv xuas nrig sib raug los ntawm cov cua sov ntawm cov ntawv yas thiab compressing lub siab zoo thiab tsis zoo. Cov khoom siv no muaj plaub qhov chaw ua haujlwm rau kev tsim, qhov punching, ntug xuas nrig ntaus, thiab stacking thiab palletizing, uas tuaj yeem ua tau raws li cov kev xav tau ntawm kev lag luam sib txawv thiab xyuas kom zoo thiab sib xws ntawm cov khoom.

Tshuab Parameters

| Moulding cheeb tsam | Clamping quab yuam | Kev khiav ceev | Daim ntawv thickness | Tsim qhov siab | Kev tsim siab | Khoom siv |

| Max. Pwm Qhov ntev | Clamping Force | Qhuav Cycle Speed | Max. Daim ntawv Thickness | Max.Foming Qhov siab | Max.Air Siab | Khoom siv tsim nyog |

| 820 x 620 mm | 80t ua | 61 / lub voj voog | 1.5 hli | 100 hli | 6 Bar | PP, PS, PET, CPET, OPS, PLA |

Nta

Tsis siv neeg tswj

Cov khoom siv tau txais kev tswj hwm zoo tshaj plaws, uas tuaj yeem tswj hwm qhov tsis xws li cua sov, lub sijhawm molding thiab siab kom ntseeg tau tias kev ruaj khov thiab sib xws ntawm cov txheej txheem molding.

Kev hloov pwm ceev

4-chaw nres tsheb thermoforming tshuab yog nruab nrog lub tshuab hloov pwm ceev, uas ua kom yooj yim hloov pwm sai thiab yoog raws cov kev xav tau ntawm cov khoom sib txawv, yog li txhim kho qhov yooj yim ntawm kev tsim khoom.

Kev txuag hluav taws xob

Cov cuab yeej siv thev naus laus zis txuag hluav taws xob, uas txo cov kev siv hluav taws xob zoo, txo cov nqi tsim khoom, thiab yog ib puag ncig zoo tib lub sijhawm.

Yooj yim rau kev khiav lag luam

Lub 4-chaw nres tsheb thermoforming tshuab yog nruab nrog kev ua haujlwm yooj yim interface, uas yooj yim rau kev khiav lag luam thiab kawm tau yooj yim, txo cov neeg ua haujlwm kev cob qhia cov nqi thiab cov nqi ntau lawm.

Daim ntawv thov

4-chaw nres tsheb thermoforming tshuab tau dav siv hauv kev lag luam ntim khoom noj, thiab tshwj xeeb tshaj yog tsim rau cov tuam txhab tsim cov khoom yas ntawm cov nplai loj vim nws cov kev ua haujlwm siab, muaj peev xwm thiab yoog raws.

Kev qhia